WesTech engineering, with over thirty years experience in the development of, and manufacturing of specialized Abandonment and Recovery Winch Systems meets and exceeds any customers critical project requirements. System redundancy can be designed into any system providing for complete control backup. WesTech’ s list of satisfactorily completed projects includes those supplied to the military, deep-water drilling, supply work over vessel, and additional heavy equipment handling applications, worldwide.

WesTech Products

WesTech Pipe Tensioning Equipment is engineered specific to customer requirements:

- Can accurately hold linear tension on pipelines laid offshore using constant tension.

- Offered in both electric and hydraulic drive utilizing digital electronic controls.

- Power supplies design optimizes performance of the equipment.

- Suspension suitable for range of pipe diameters and coatings.

- Accommodates wide range of track to pipe contact compliance.

- Suitable for use with tubing or umbilical laying operations.

- Tension capacity up to 100,000 pounds of linear tension at 100 feet per minute.

- Maximum pipe diameter up to 30 inches.

The CFI WesTech Pipe Handler System is designed to store pipe, pick pipe up and present it to the derrick for drilling, production or workover applications.

CFI Pipe Handler System Capabilities:

WesTech Pipe Handler System is engineered to each specific customer’s requirements:

- Designed to deliver pipe or tubular products to the derrick with Telescopic Skate.

- Carry’s pipe/tubulars to and away from the derrick for transfer by overhead crane.

- Pipe/tubular capability includes: Risers, Drill Pipe, Casings and Drill Collars.

- Tubular Weight Limit: 6,500 lbs. per joint.

- Tubular Capacity on Skate: Casing – 30” O.D.; Riser with Buoyancy (50”dia. x 75’ Long); Telescopic Riser (26” dia. x 78’ Long) and maximum Weight 80,000 lbs. with landing pad and support adaptor.

- Multiple joints of tubulars can be loaded onto Indexer Ramp Arms for delivery staging.

- Maximum Tubular O. D. on Indexer Ramp Arms: Casing- 13.38”; Drill Pipe- 6.5”; Drill Collars- 9.5”.

- Indexer Ramp Arm Capacity: Tubular Length 28-45 FT.

- Maximum Skate Speed: Pipe Skate – 400 FPM; Main Skate – 200 FPM.

- Cycle Rate: one joint/minute.

WesTech Pipe Handling Equipment is engineered to specific customer requirements:

- CFI Pipe Handling Equipment is available for both onshore and offshore pipeline fabrication applications.

- Pipe Handling Equipment is designed and manufactured to meet specific customer requirements utilizing standard CFI designed components.

- Modular equipment design provides system components capable of meeting specific project requirements with minimal adaptation or change.

- Both electric and engine driven Hydraulic Power Units available with control system designed to meet system requirements.

- Designed for coated or uncoated pipe diameters up to 60 inches.

Pipe Lay Tensioning Systems

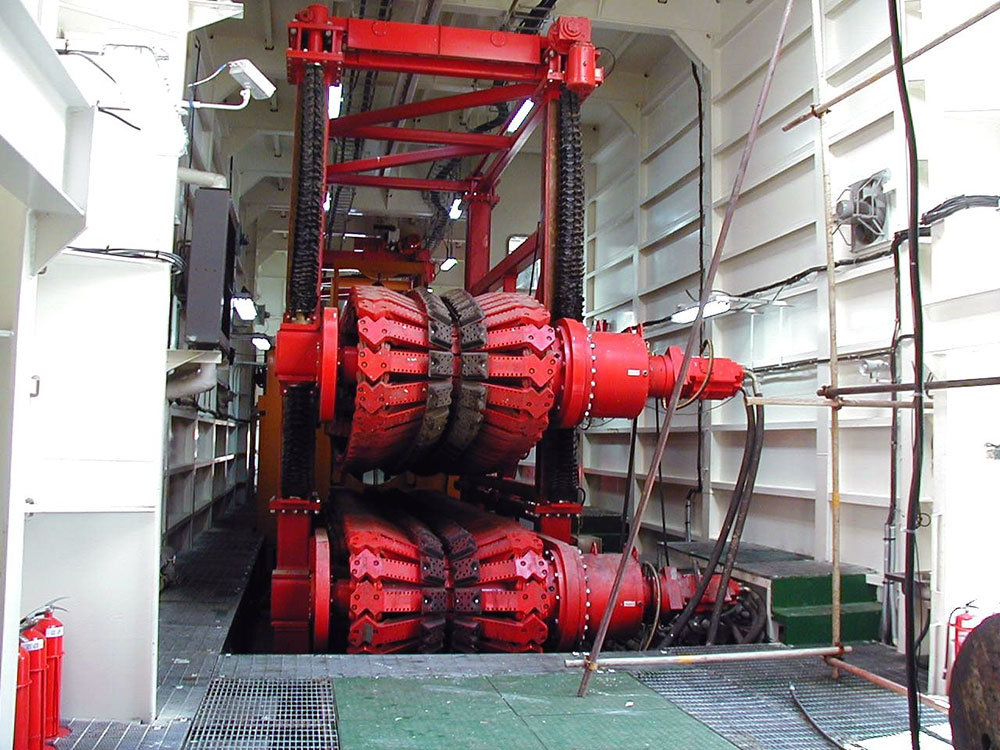

WesTech Pipe Lay Tensioner Equipment is engineered to each specific customer's critical requirements. Pipe Tensioners are track-type tension systems capable of holding back on the pipeline, using constant tension characteristics. Pipe Tensioners absorb the curvature of the pipeline and accommodate nominal changes in coating diameter. Available drives include electric, electro-hydraulic or diesel-hydraulic power units. Control is by solid-state integrated electronic digital circuitry.

Single Pipe Tensioners can be arranged in multiple tandem units to obtain higher tension when required. Welding or other workstations may be located between tandem units depending on barge installation.

LINEAR PIPE TENSIONERS

CFI- WesTech Linear Pipe Tensioners are engineered to each customer’s exact specification and requirements. CFI-WesTech equipment is in use on pipe-lay vessels of various descriptions all over the world, operating in all kinds of ambient conditions. CFI- WesTech offers a variety of Linear Pipe Tensioners (LPT’s) designs and sizes to fit nearly any customer requirement.

CFI-WesTech LPT’s are capable of maintaining accurate tension on the smallest diameter pipe or electric cables all the way up to machines capable of handling pipe joints as large as 60 inches outside diameter. If required, these tensioners can be adapted to handle pipe up to 72 inches outside diameter. Multiple Pipe Tensioners can be operated in tandem to increase the maximum tension capacity and/or to provide flexibility and redundancy to pipe-lay operations.

CFI-WesTech equipment is typically controlled and monitored through the use of PLC based Digital Electronic Control Systems (DECS) and can be electrically or hydraulically driven. In some applications, simple hydraulic controls can be provided for use with on smaller equipment.

LINEAR PIPE PUSHERS

CFI- WesTech offers a specialized version of our “E” Series Pipe Tensioner, has the capability to pull or push pipe with equal force. The “Linear Pipe Pusher” (LPP) is used in land based pipe spooling yards for pipeline applications, where the pipe joints are pre-fabricated on shore, then transferred onto holding racks, and then spooled onto pipe-lay vessels utilizing the “reeled pipe” method of pipe-lay.

The LPP can also be easily adapted to provide hold-back tension during spooling operations as well.

LINEAR PIPELINE RECOVERY MACHINES

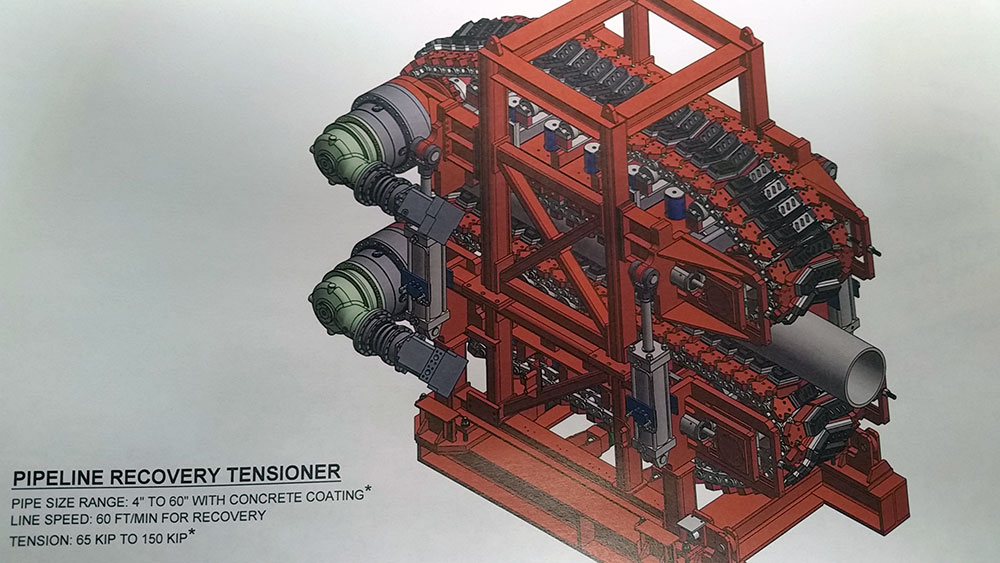

CFI- WesTech has recently developed its new Linear Pipeline Recovery Machine (LPR). This patented design technology is specifically applicable to pipeline decommissioning applications as mandated by regulations in many countries to recover and dispose of abandoned pipelines and flow lines.

The LPR machine operates much like a Linear Pipe Tensioner, with its primary function to aid in the recovery of previously laid pipelines which are no longer in use. The (LPR) machine is designed for use on a pipe-lay, or other similar vessels to reverse lay (recover) pipelines currently on the seabed. The design facilitates gripping forces not achievable on any known existing equipment of comparable size. Either concrete covered or bare pipe can be gripped and held firmly by the (LPR) machine as the pipe is in-hauled during the recovery of the submerged pipeline. Various gripping pad designs, best suited to the particular surface/coating, can be utilized as applicable.

For added versatility and economic utilization, the (LPR) machine can also be used and operated as a normal Linear Pipe Tensioner, when equipped with standard traction pads. Plus, a portable version is available to provide additional flexibility and utilization.

LINEAR CABLE LAYING TENSIONER

The Linear Cable Laying Tensioner is designed for use on various vessels as a portable or permanent installation. The surface pressure is very low to prevent damage to the cable or tube being laid. The (CLT) machine represents the ability of CFI-WesTech to produce equipment to the specific requirements dictated by the customer’s needs. Our equipment is always a fully engineered solution.

CUSTOM DESIGNED LINEAR PIPE TENSIONERS

For more information on any CFI-WesTech Linear Pipeline Machines and equipment, contact Control Flow, Inc.’s WesTech Operation with the following information:

- maximum pipe tension required

- maximum pipe speed possible during vessel movement

- maximum pipe weight per joint

- average pipe joint length

- type of pipe coatings expected

- pipe joint maximum outside diameter, including the coating

- choice of electric VFD driven tracks or hydraulic motor driven tracks (Note: Engine driven power units or electrically driven power units can both be supplied. Starboard side, Port side)

- ramp orientation on the pipe lay vessel (Note: Center lay pipe ramp orientation dictates certain design considerations of the linear pipe tensioner and are critical for determining equipment)

- other equipment details will be determined by the exact application and typically are vessel specific

- if any equipment including LPT’s are available to be moved from one vessel to another

- any requirement for portability in the required pipe tensioner system

CFI- WesTech offers a specialized version of our “E” Series Pipe Tensioner, has the capability to pull or push pipe with equal force. The “Linear Pipe Pusher” (LPP) is used in land based pipe spooling yards for pipeline applications, where the pipe joints are pre-fabricated on shore, then transferred onto holding racks, and then spooled onto pipe-lay vessels utilizing the “reeled pipe” method of pipe-lay.

The LPP can also be easily adapted to provide hold-back tension during spooling operations as well.

CFI- WesTech has recently developed its new Linear Pipeline Recovery Machine (LPR). This patented design technology is specifically applicable to pipeline decommissioning applications as mandated by regulations in many countries to recover and dispose of abandoned pipelines and flow lines.

The LPR machine operates much like a Linear Pipe Tensioner, with its primary function to aid in the recovery of previously laid pipelines which are no longer in use. The (LPR) machine is designed for use on a pipe-lay, or other similar vessels to reverse lay (recover) pipelines currently on the seabed. The design facilitates gripping forces not achievable on any known existing equipment of comparable size. Either concrete covered or bare pipe can be gripped and held firmly by the (LPR) machine as the pipe is in-hauled during the recovery of the submerged pipeline. Various gripping pad designs, best suited to the particular surface/coating, can be utilized as applicable.

For added versatility and economic utilization, the (LPR) machine can also be used and operated as a normal Linear Pipe Tensioner, when equipped with standard traction pads. Plus, a portable version is available to provide additional flexibility and utilization.

The Linear Cable Laying Tensioner is designed for use on various vessels as a portable or permanent installation. The surface pressure is very low to prevent damage to the cable or tube being laid. The (CLT) machine represents the ability of CFI-WesTech to produce equipment to the specific requirements dictated by the customer’s needs. Our equipment is always a fully engineered solution.

CUSTOM DESIGNED LINEAR PIPE TENSIONERS

For more information on any CFI-WesTech Linear Pipeline Machines and equipment, contact Control Flow, Inc.’s WesTech Operation with the following information:

- maximum pipe tension required

- maximum pipe speed possible during vessel movement

- maximum pipe weight per joint

- average pipe joint length

- type of pipe coatings expected

- pipe joint maximum outside diameter, including the coating

- choice of electric VFD driven tracks or hydraulic motor driven tracks (Note: Engine driven power units or electrically driven power units can both be supplied. Starboard side, Port side)

- ramp orientation on the pipe lay vessel (Note: Center lay pipe ramp orientation dictates certain design considerations of the linear pipe tensioner and are critical for determining equipment)

- Other equipment details will be determined by the exact application and typically are vessel specific

- If any equipment including LPT’s are available to be moved from one vessel to another

- any requirement for portability in the required pipe tensioner system