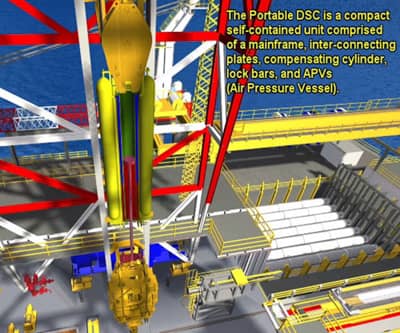

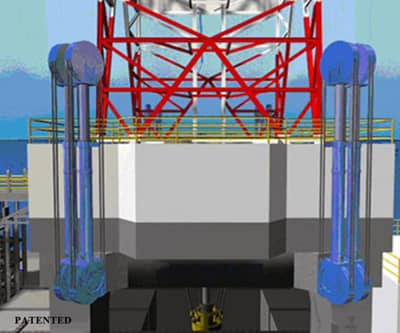

Control Flow’s newest Drill String Compensator features the latest and most improved technology in the industry. The benefits are lighter weight, improved operational reliability, and better “Weight On Bit“ performance. Available in both 20 and 25 foot stroke lengths, this new DSC is suitable for both new installations and upgrades of your present Drilling Package.

Contact Control Flow, Inc. and let us show you the benefits of using the CFI DRILL STRING COMPENSATOR as part of your rigs drilling equipment /motion compensation package.

Control Flow/Mo-Comp Products

Capacities:

- 400K Compensating / 1300K Mechanical Lock

- 600K Compensating / 1600K Mechanical Lock

- 800K Compensating / 1800K Mechanical Lock

Control Flow DSC Design Features:

- Rod End Down/Tension Rod Design

- Hydraulic Fluid Operated Cylinder/More Positive Control

- Accumulators Repositioned From Mast to DSC

- Air Powers DSC Up To DSC Mounted Accumulators

- Quick Acting Flow Control Valve

- Increase/Decrease Control Via Remote Air Control Skid

- Touch Screen HMI For Electronic Control and Monitoring

- APV Gas Energy Conversion to Fluid At DSC

- Cylinders Direct Tension Loaded 1:1

- Maximum Working Pressure 3500 PSI

- No Pressure In Drillers House

- Only Two Hydraulic Locking Valves Required

- No Chains To Maintain, Adjust or Cause Misalignment

- No Bearings Required

- No Air-Oil Reservoir Required

- Mechanical Lock

- Smaller Cylinders and Lighter Weight Than Other DSC’s

- Improved Design Provides Greater Compensation and Lower Weight On Bit Variation Than Other Designs

- Adaptable to All Traveling Blocks and Top Drives and For All DSC Replacements and Upgrades