ADVANTAGES:

- Design based upon field proven product improvements

- Most reliable annular bop packing/seal used in industry

- Greater capability permitting stripping of pipe under well pressure

- Only two moving parts and long piston style

- Strong space and weight saving forged body

- Wear bands to protect against metal to metal interferance and wear

- Feedable packing unit

- Piston conical bowl design

- Packing flange steel inserts

- Pressure energized seals

- Seals and parts available world wide

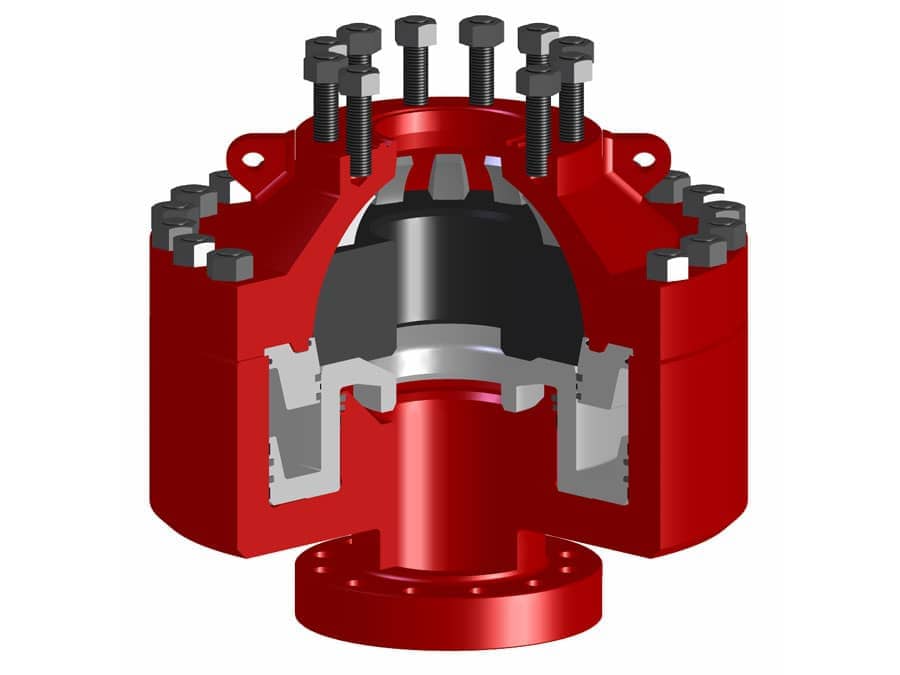

Control Flow Type S Annular BOP’s with only five major components including the seal/packer unit, they are particularly qualified to meet the industry’s needs for simple, reliable and proven continual use and protection. Type S packing units are manufactured from high quality rubber material reinforced with flanged steel segments. Operating at lower working pressures than other annular BOP designs the Type S seals on open hole as well as a variety of different shapes and sizes of Kelly’s, tool joints, drill pipe and drill collars, casing, tubing and even wire line. This proven spherical design is available in a full range of annular sizes and pressure ratings where safe, reliable, and proven capability are required.

SIZE AND PRESSURE RANGES:

- 7-1/16”- 3M/5M/10M (S TYPE)

- 11”- 3M/5M/10M (S TYPE)

- 13-5/8”- 3M/5M/10M (S TYPE)

- 16-3/4”- 5M (S TYPE)

- 18-3/4”- 10M (S TYPE)